Ahmed Aly, a student at Lincoln Memorial University’s School of Engineering, has combined creativity and cutting-edge technology to solve an automotive challenge using 3D printing. Aly designed and printed a custom part for his car using the school's 3D printer, showcasing how LMU students apply practical skills to enhance their educational experiences.

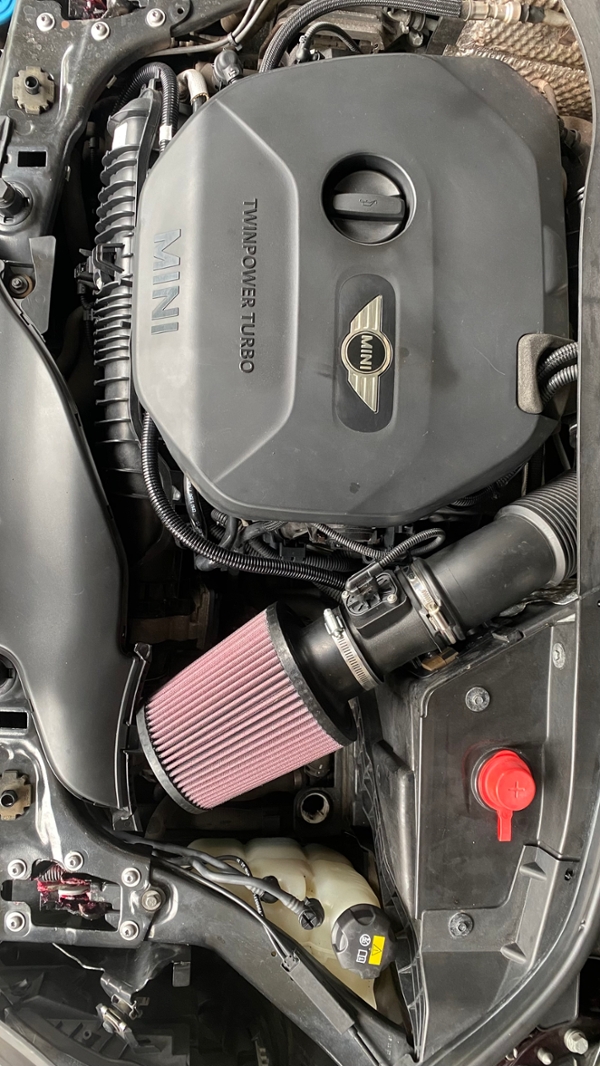

Aly designed a short pipe to replace his vehicle’s air filter box, creating what is commonly known as a "cold air intake." This modification typically enhances turbo and induction noises while slightly boosting performance. Commercially available cold air intakes cost hundreds of dollars, but Aly’s innovation allowed him to design his own for a fraction of the price. He spent just $70 for materials, including the printing filament and a cone filter.

“The main reason for the cold air intake is to increase turbo and induction noises while offering a very slight increase in performance,” Aly explained. “I decided to 3D print it mainly due to the cost but also to gain experience with 3D design. It was a fun personal project with no deadlines.”

The project provided valuable hands-on experience. After designing the part, Aly spent time refining measurements and making adjustments until the part fit perfectly in his car.

“The Mass Airflow Sensor (MAF) was meant to attach to the pipe to avoid getting a check engine light. Getting the socket and screw holes right was the hardest part,” he said.

Another significant challenge was finding a filament that could withstand the high temperatures of the engine bay which can reach up to 250°F. Aly selected a carbon fiber nylon filament capable of handling nearly 400°F. The final product met the functional requirements and fit seamlessly into the vehicle’s engine bay.

Another significant challenge was finding a filament that could withstand the high temperatures of the engine bay which can reach up to 250°F. Aly selected a carbon fiber nylon filament capable of handling nearly 400°F. The final product met the functional requirements and fit seamlessly into the vehicle’s engine bay.

“Having the part in my hand after all the work I put into it was one of the most satisfying things I’ve ever felt. The achievement wasn’t just about getting the intake; it was about having a functioning part that I created entirely by myself,” Aly added.

This project is only the beginning for Aly. He already has several other small projects lined up, using 3D printing for vehicle modifications that are more affordable and customizable than ordering parts online.

“I'll likely consider 3D printing for any problem that presents itself from here on out,” he said. “The main benefits that I see are the cost savings and the customization that it gives you. I designed the part to function exactly how I wanted it to. I could modify its size to allow more air in, add custom logos, or modify its placement. There are as many customization options as your mind allows.”

LMU’s School of Engineering is proud to support students like Aly in their pursuit of hands-on learning opportunities, encouraging innovation and creativity while preparing them for future careers in engineering and technology.

Lincoln Memorial University is a values-based learning community dedicated to providing educational experiences in liberal arts and professional studies. The main campus is in Harrogate, Tennessee. For more information about the undergraduate and graduate programs available at LMU, contact the Office of Admissions at 423-869-6280 or email at admissions@lmunet.edu.